Equipments

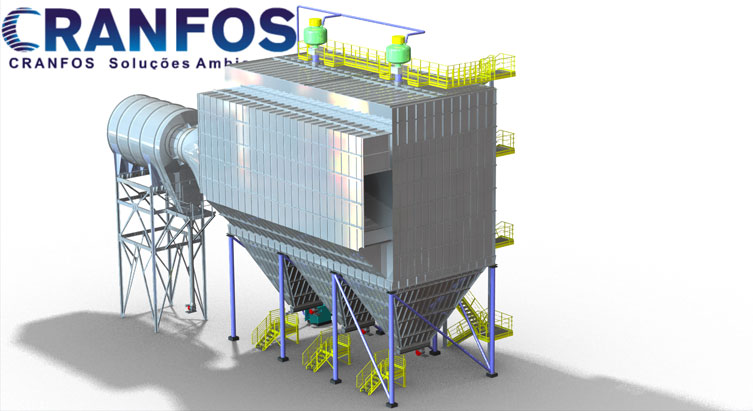

Bai-Press 10™ Bag Filter

With cutting-edge technology, this piece of equipment performs dry filtration of process gases, and is named after the type of cleaning that it undergoes. Like the Bag Filter High-Pressure, it is use to filter several forms of particulate matter from industrial customer process gases the flow of which is forced by exhaustion, providing a continuous gas filtering operation through its bags.

The main difference between this filer type and a High-Pressure Bag Filter lies in the fact it uses air at a low pressure to clean the bags. As time goes by, the gas filtration retains particulate matter on the outer surface of the bag, thereby reducing the gas flow area and, as a result, increasing the load loss on the fan.

At this point comes the cleaning system which blows low-pressure compressed air into the system, more specifically inside the bags, causing a slight agitation on the entire bag, which is required for releasing the particulate matter that it retains. This air blowing is electronically controlled by a PLC programmed for automatic operation. Such control is provided by exclusive equipment and devices which use our own technology to allow the compressed air, at a certain pressure, to be blown by a rotary system that drives the air jet to each bag, the necessary agitation.

Unlike the one used in high-pressure bags filter (in fact, used by all of our competitors), this type of cleaning winds up drastically shortening the service life of each bag, requiring the set of bags to be replaced with a new one at a high frequency. Our technology provides our bags with a much longer service life, as they are not constantly subject to shockwaves that damage their construction.

Once the particulate matter is shaken, it is released from the bag surface and falls down to the bottom of the hopper where it is stored until transportation/packing. Such transportation is also taken into consideration in the designing of the bags, so that a piece of equipment can be built with different hopper arrangements, which will identify the best outflow control type for this material, such as a screw conveyor, for longitudinal hoppers, or just a rotary valve, for pyramidal hoppers. Sets can even be put together with the two of these pieces of equipment, whether or not using a slide valve for added control.

Our bags, which are critical items for proper operation and efficiency of the equipment and, for this equipment model, feature superior service life, have the appropriate characteristics for each type of process, where variables like temperature and gas composition make the choice of bag type very important, as such variables will also either increase or decrease the total load loss for sizing and specifying the fan that will exhaust gases through pipes and exhaust hoods and into the filter.

With cutting-edge technology from Germany, the bags used in our equipment are manufactured with the finest materials on the market, as well as highly sturdy and easy to maintain. They are manufactured according to advanced manufacturing processes, their cost is no impediment to our filters being financially attractive.

The same goes to our cages and other fastening systems in terms of description, as they are tailored to each design and suitable to each kind of industrial process. The extensive technology possessed by CRANFOS allows filter designs to be developed more freely for very high gas flow rates, without prejudice to efficiency or any structural problems in our equipment.

Different standard types of inlets will influence the types of table roll baffle for internal protection of bags and other internal components which are sized so as not to cause any major load loss in the system. For internal maintenance and safety, dampers are used, where required, to control the gas flow in each chamber.

Other features that make this type of filter superior to high-pressure ones include very low maintenance —which is also much easier due to a clean gas plenum height that allows technicians to enter for bag maintenance purposes—, and the smaller area required for installing it —as the bag is differentiated in shape to enable a smaller filter assembly.